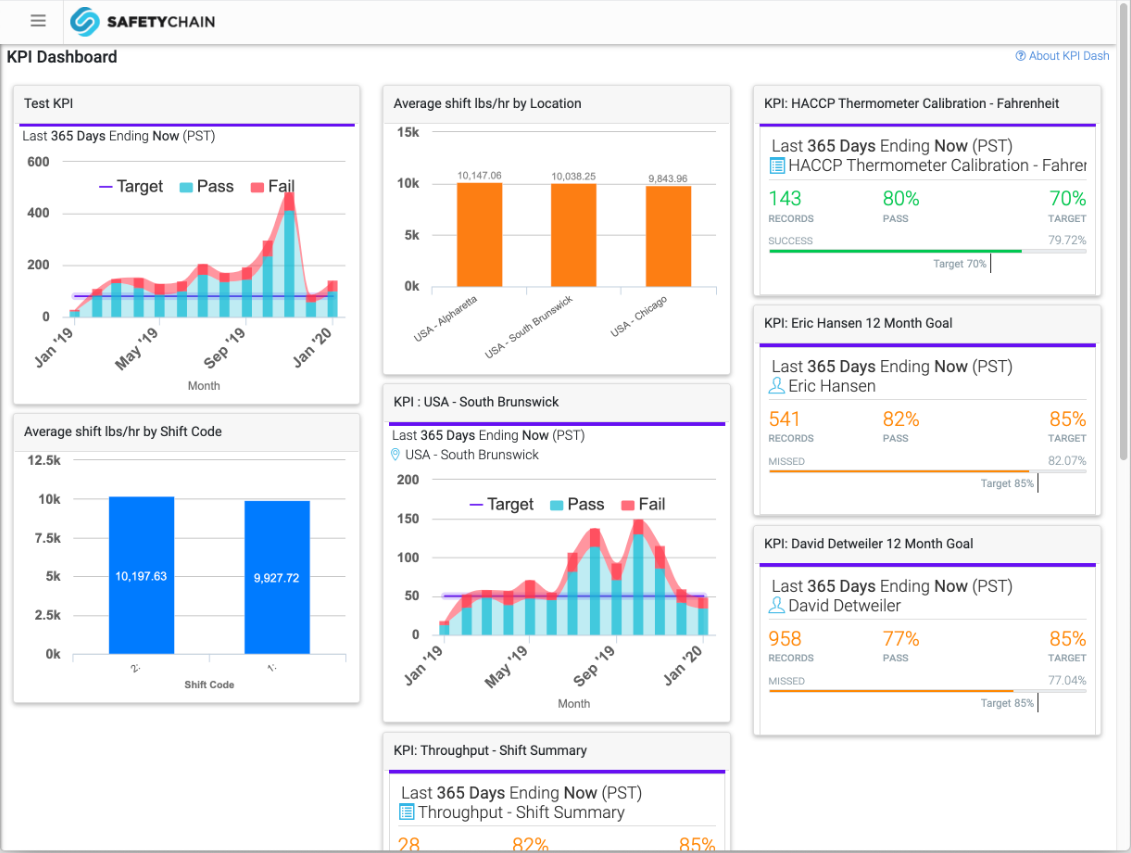

“SafetyChain was built distinctively for QA. It trends data and has the ability to customize reports and dashboards without any add on costs or technical abilities. For us, a better fit for our business was SafetyChain.”

SafetyChain Quality Manager puts busy FSQA teams in control of their yield, costs, and program compliance with a fully-integrated Quality Management Software (QMS) solution. From real-time specification verification to automated audits for regulatory, GFSI, and customer requirements, SafetyChain helps drive a completely paperless process for quality assurance and compliance.

“SafetyChain was built distinctively for QA. It trends data and has the ability to customize reports and dashboards without any add on costs or technical abilities. For us, a better fit for our business was SafetyChain.”

The only native application purpose-built for every major operating system.

Access on your phone, tablet, PC/laptop, or floor workstation in online or online WiFi mode.

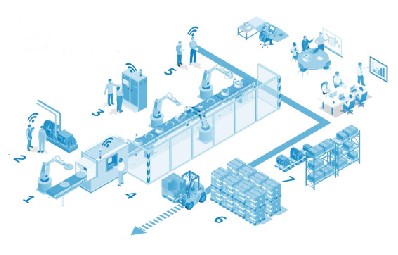

Leverage mobile and automated data collection via tablets, sensors, PLCs, & API system integrations.

What would it look like to eliminate paper & point solutions for your team?

Quickly, easily, and accurately collect critical food safety and quality data on any device (tablet, PC, or workstation) with a single submission that instantly syncs with your GFSI, regulatory, and customer requirements. Save valuable time and ensure your records are always safe, stored, and accessible for your team or disaster recovery.

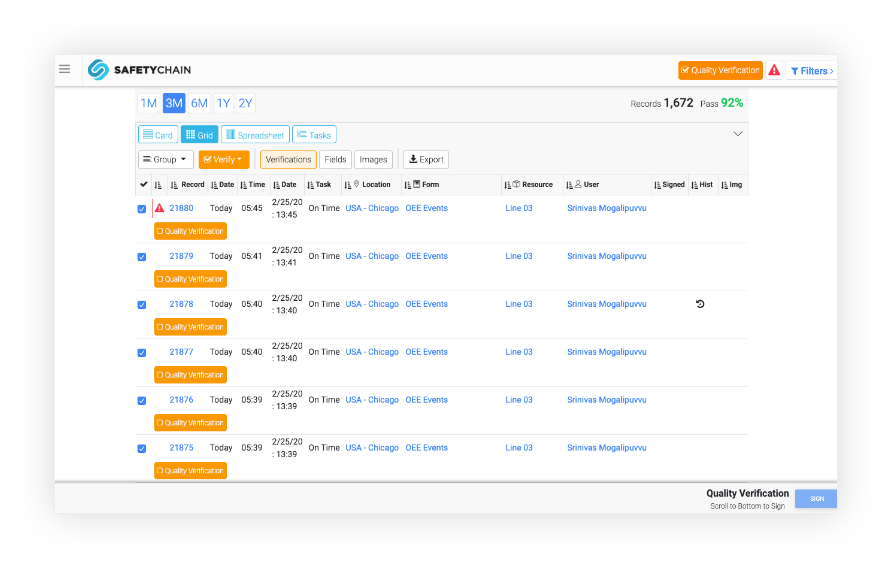

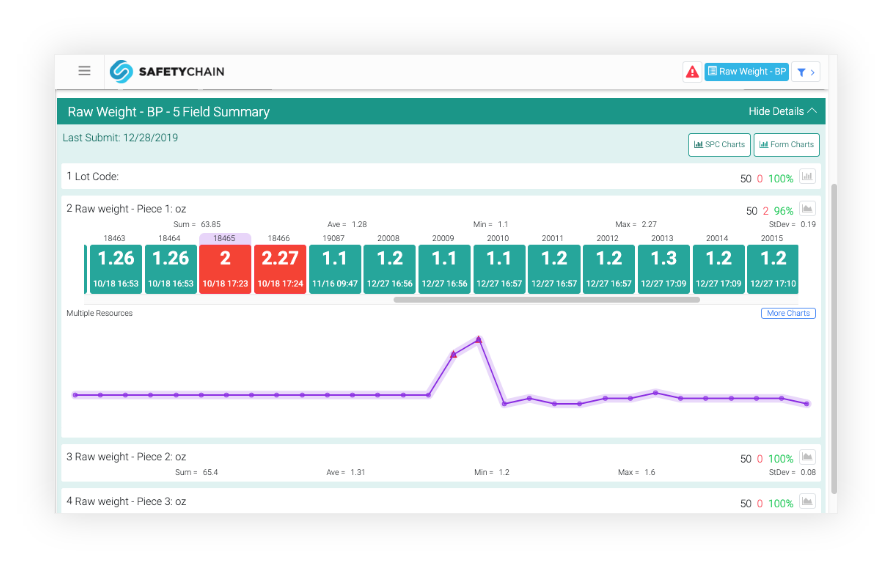

Identify potential non-conformance issues faster with real-time verification to ensure all product leaving your facility meets internal and customer specifications. Achieve less waste and improve on-time shipments for fewer complaints from happier customers.

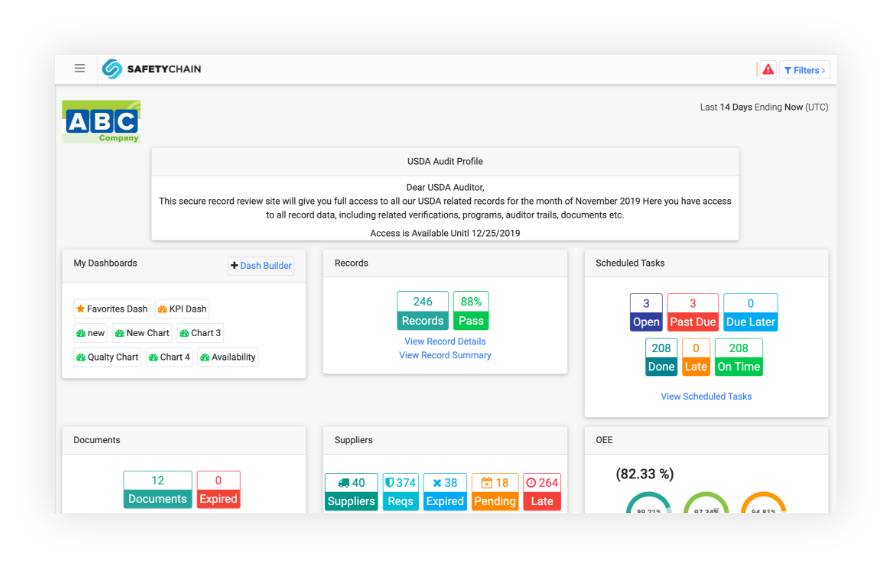

With a single click, create a fully auditable record with every form submission for every plant across the enterprise. Records are instantly available for selected team members to review, sign off, and report on or share selected records using Secure Profiles for customers, auditors, and even regulatory agencies. Eliminates 80% of your preparation time instantly.

Customer Case Study: Learn how Sokol & Company went 100% paperless and automated the entire audit process.

User-friendly app to easily collect data, eliminate errors & drive accountability.

Real-time data to make better, faster decisions without duplicate/delayed data entry.

Enterprise-wide performance and trending analysis to ensure compliance & maximize yield.