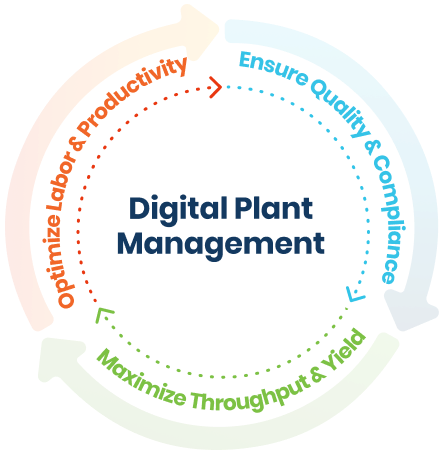

Digital Plant Management

Unite Quality & Production to Improve Plant Performance

Over 2,000 Facilities use SafetyChain to empower teams to optimize labor, maximize yield & ensure quality.

The Convergence of Quality & Production

Flexible for what you need today, scalable for what you want tomorrow.

Maximize Throughput

and Yield

Ensure Quality and Compliance

Defined processes and audit-ready documentation reduce costs and put quality at the heart of the manufacturing process.

Optimize Labor and Productivity

Visibility, on-board BI tools, and automation build a culture of teamwork, accountability, and continuous improvement to increase labor efficiency.

A single platform to unify plant-wide data, insights, and growth

Digital Data Capture

Digitally capture and unify data from multiple sources including operators, machines, sensors, PLCs, and devices. Gain real-time visibility into what is happening throughout your facility.

Inform & Empower

Visualize data with role-based dashboards to conduct real-time and historical analysis. Know if you are hitting your production goals while the line is running and use trends to pinpoint areas of improvement.

Automation & Workflows

Drive plant processes, track compliance, and prepare for audits with programmatic documentation and role-based automated workflows. Eliminate guesswork on the plant floor and ensure audit-readiness so everyone knows what they need to do and when.

Continuous Improvement & Value

Make adoption easy with a training environment and support from our coaching team. Establish key metrics that ensure both the short-term and long-term success of your investment.

The Power of Digital Plant Management

Customer Success in 2,000+ Locations & Growing

“Now that we have SafetyChain, our team can’t wait until our next audit!”

“In solving our paper problem we actually ended up solving a much bigger business problem with SafetyChain.”

“SafetyChain trends data and allows us to configure reports without any add-on costs or technical abilities. For us, it was a better fit.“

Learn how SafetyChain increases performance across the entire shop floor and enterprise >>