“In solving our paper problem we actually ended up solving a much bigger business problem with SafetyChain.”

Tracy Ouellet – Corporate Applications Manager

Digital Plant Management helps reduce unplanned downtime by combining data captured from equipment and service checklists to help guide manufacturing maintenance activities and priorities. With SafetyChain, operators and technicians stay informed with configurable and contextualized alerts that enable them to return lines to service rapidly.

◼ Extend Equipment Lifespan

◼ Streamline Scheduling

◼ Optimize Resources

◼ Avoid Manufacturing Scrap & Rework

◼ Automate Data Collection

◼ Diminish Documentation Time

◼ Speed Up Repairs & Inspections

◼ Reduce Downtime & Optimizes Operations

◼ Enable Regulatory Compliance

◼ Standardize Maintenance Processes

◼ Work Order Visibility

◼ Preventative Maintenance Accountability

“In solving our paper problem we actually ended up solving a much bigger business problem with SafetyChain.”

Tracy Ouellet – Corporate Applications Manager

The only native application purpose-built for every major operating system.

Access on your phone, tablet, PC/laptop, or floor workstation in online or online WiFi mode.

Leverage mobile and automated data collection via tablets, sensors, PLCs, & API system integrations.

See how Preventative Maintenance works in Digital Plant Management

Use automated equipment checks to identify which machines need work and when. Startup, changeover, and unplanned production downtime can be configured to be displayed by affected equipment and reason code, allowing you to direct your technicians to the most urgent problems first. Make timely, effective decisions for preventative maintenance, repairs, and calibrations to increase the lifespan of your assets and maximize production time.

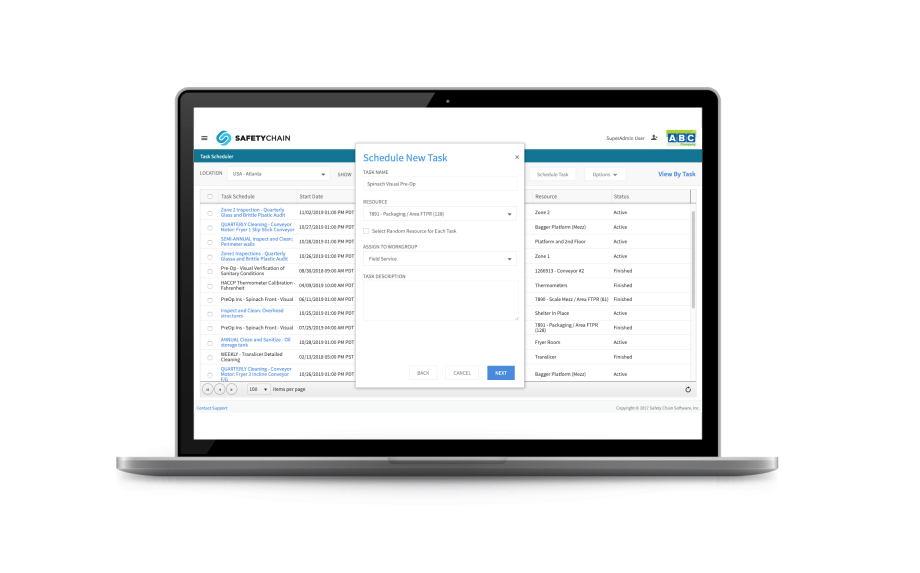

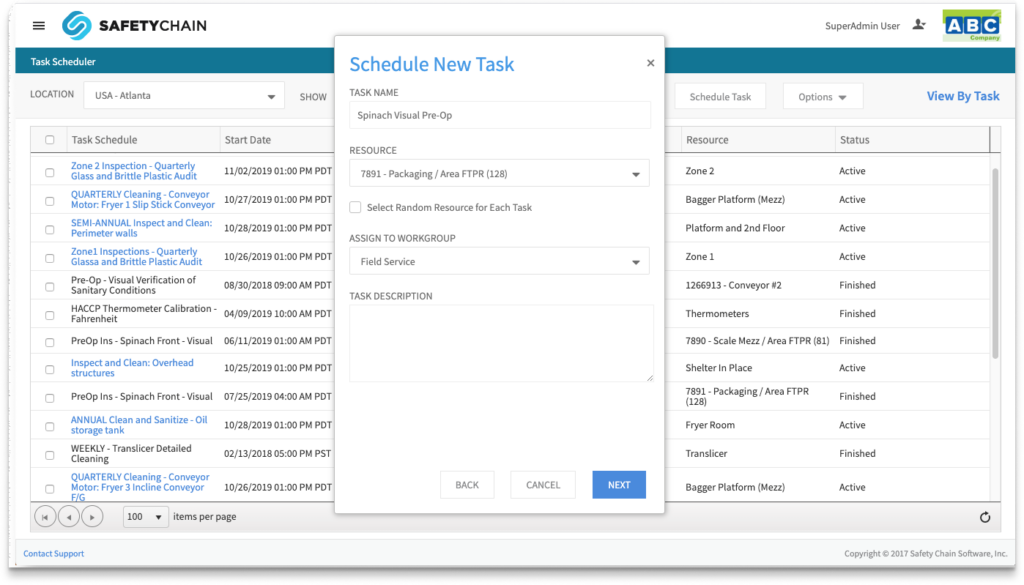

Keep maintenance teams on track with facility-wide task scheduling. Centrally manage one-off work orders or recurring maintenance and calibration. Align employees on the plant floor with company goals through a user-friendly interface that sorts tasks by priority and due date to help workers stay on track.

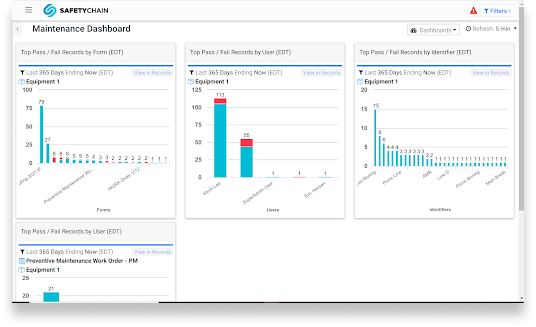

Utilize web, mobile, and floor-friendly production dashboards to actively monitor availability, performance, and root cause analysis across all your plants to help make better, faster operational decisions that drive continuous improvement.

Easy-to-use solution that eliminates data entry errors and helps identify line & spec issues faster.

Full visibility into real-time plant performance to make better, faster decisions to drive continuous improvement.

Complete enterprise wide visibility and control to monitor performance and profitability from the palm of your hand.