“In solving our paper problem we actually ended up solving a much bigger business problem with SafetyChain.”

Tracy Ouellet – Corporate Applications Manager

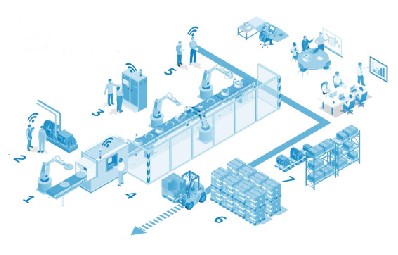

POWER QUALITY & PRODUCTION WITH REAL-TIME ANALYTICS

Operators need smarter tools to make adjustments while the line is running. Digital Plant Management reduces the risk of costly non-conformances by automating quantitative data collection and leveraging quality tools like control charts to enable real-time process monitoring.

◼ Diminish Margin of Error

◼ Increase Customer Satisfaction

◼ Reduce Scrap, Rework, & Warranty Claims

◼ Improve Resource Utilization

◼ Boost Operational Efficiency

◼ Decrease Tribal Knowledge

◼ Faster Problem Resolution

◼ Streamline Inspection Processes

◼ Better Product Uniformity

“In solving our paper problem we actually ended up solving a much bigger business problem with SafetyChain.”

Tracy Ouellet – Corporate Applications Manager

The only native application purpose-built for every major operating system.

Access on your phone, tablet, PC/laptop, or floor workstation in online or online WiFi mode.

Leverage mobile and automated data collection via tablets, sensors, PLCs, & API system integrations.

See how Process Control works in Digital Plant Management

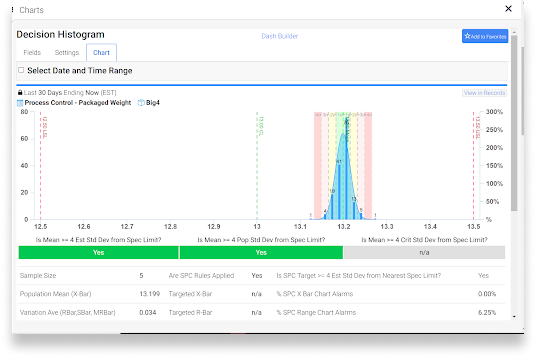

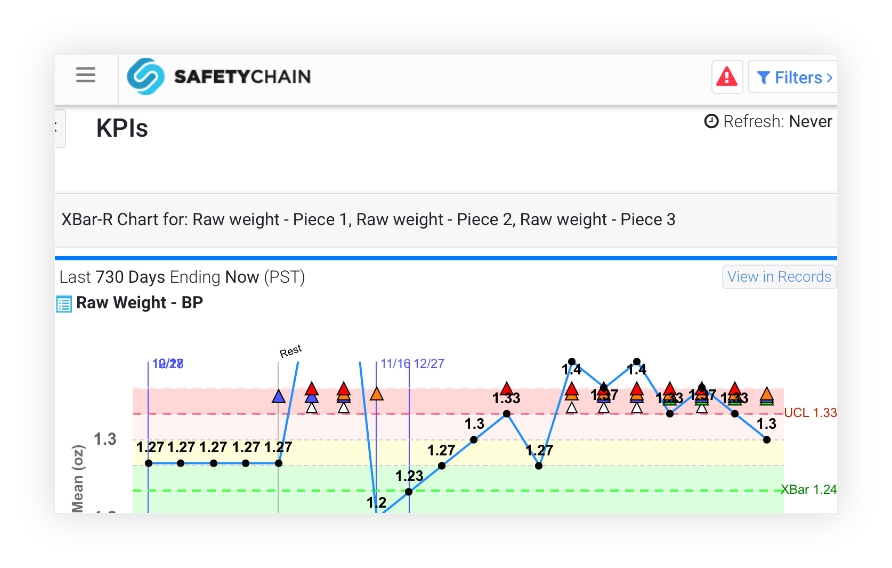

Improve yields by tightening control and specification limits to reduce giveaway or overcook. Set customized specification ranges and receive automated alerts any time processes exceed acceptable thresholds. Ensure compliance with regulatory, industry, and customer requirements by setting control and specification limits and tracking production in real-time. Preempt non-conformances and receive instant notifications of deviations. Plus, observe trends over time to maintain consistency, efficiency, and quality output during every shift.

Use real-time SPC data on tablets, work stations or moblie phones to reveal bottlenecks, manage behaviors, and discover solutions for production problems. Identify problems before they exceed specification thresholds by using run rules and configurable control limits to stop non-conformance before it starts. Address issues immediately and uncover their root causes to reduce waste, rework, and returns, while also improving on-time shipments to delight your customers.

Easy-to-use solution that eliminates data entry errors and helps identify line & spec issues faster.

Full visibility into real-time plant performance to make better, faster decisions to drive continuous improvement.

Complete enterprise wide visibility and control to monitor performance and profitability from the palm of your hand.