“In solving our paper problem we actually ended up solving a much bigger business problem with SafetyChain.”

Tracy Ouellet – Corporate Applications Manager

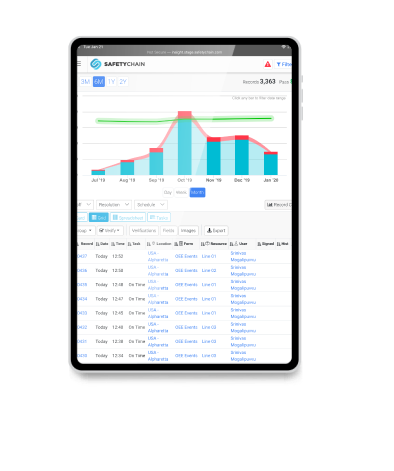

Understand the true performance of every shift, line, batch, and facility. SafetyChain’s Plant Management Platform takes the hassle out of tracking and trending data from equipment, PLCs, SCADA, and sensors and enables you to always have a pulse on your plant’s operations.

◼ Increase Customer Satisfaction

◼ Diminish Margin of Error

◼ Increase Customer Satisfaction

◼ Improve Resource Utilization

◼ Boost Operational Efficiency

◼ Remove Dependency on Tribal Knowledge

◼ Faster Problem Resolution

◼ Streamline Inspection Processes

◼ Better Product Uniformity

“In solving our paper problem we actually ended up solving a much bigger business problem with SafetyChain.”

Tracy Ouellet – Corporate Applications Manager

The only native application purpose-built for every major operating system.

Access on your phone, tablet, PC/laptop, or floor workstation in online or online WiFi mode.

Leverage mobile and automated data collection via tablets, sensors, PLCs, & API system integrations.

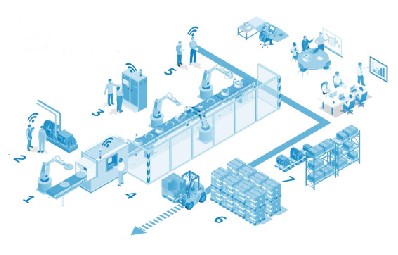

See how Digital Plant Management works across the shop floor

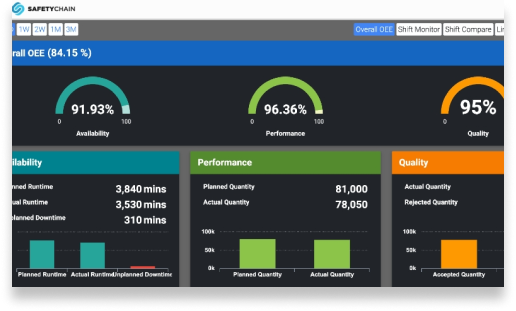

Digital Plant Management shows you how your plant is running against its full potential by measuring how much manufacturing time is actually productive. Leverage advanced analytics to get insights into production trends, planned production time, and use downtime monitoring. Use real-time insights to uncover areas of opportunity and improve production performance while the line runs.

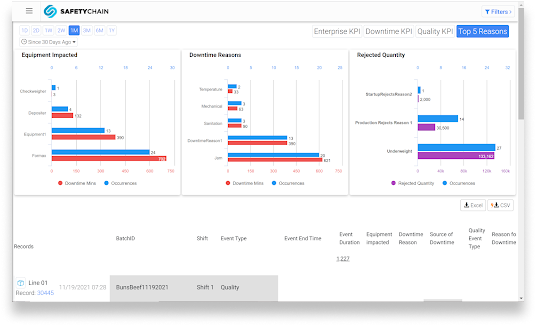

Eliminate bottlenecks by tracking OEE scores by line, shift, or other attributes. With the ability to identify the origins of production issues in real-time, you can address problems quickly before they escalate—and prevent them from happening again.

Whether you just want form-driven functionality with no automation, need to integrate into your existing equipment and devices, or somewhere in between, SafetyChain has options that keep you in confident control. Enterprise process manufacturers that have complex data automation needs can get a true picture of OEE, while smaller facilities with few lines can access the same enterprise-grade solution using operator-driven digitized smart forms, and add sensors and automation as needs change.

Easy-to-use solution that eliminates data entry errors and helps identify line & spec issues faster.

Full visibility into real-time plant performance to make better, faster decisions to drive continuous improvement.

Complete enterprise wide visibility and control to monitor performance and profitability from the palm of your hand.