Who We Serve

Solutions that power food, beverage, and CPG manufacturers

Quality, Compliance, and Production Software that Fits. Everywhere.

Whether you run a single facility focused on a niche product, or are a category leader with dozens of facilities, SafetyChain is built for how you manufacture greatness. Flexible to run the most comprehensive compliance, safety, quality, and production operations on earth, see how a complete platform can power your success.

Roots in Food & Beverage

Safety, quality, and compliance are among the biggest challenges for the food and beverage industry. SafetyChain’s agile platform was built with these needs in mind.

Unlock complete visibility into your operations and promote ongoing compliance with our robust solutions. Leverage real-time data and analytics to make smarter, faster decisions that support safety and quality while simplifying recordkeeping and ending the paperwork shuffle for good.

With all of your records in one easy-to-access location, audit prep and compliance with GFSI, FSMA, and customer requirements are simpler than ever. Plus, automated task scheduling, connection to your plant’s devices, and mobile forms give your teams the power to focus on their core responsibilities without the need for manual recordkeeping.

- Beverage

- Dairy

- Fruits, Vegetabels, & Nuts

- Meat, Poultry, & Seafood

- Sugar, Snacks, & Confections

Consumer Packaged Goods

The pressure to keep prices low while providing superior products calls for streamlined operations in CPG. Stay agile and ahead in the competitive market with a platform that drives automation while allowing you to keep the pulse on your day-to-day operations.

Achieve business intelligence maturity with real-time data and analytics, unlocking the insights that influence productivity and profitability. With SafetyChain’s comprehensive reporting features and simple, all-in-one platform, you’ll have access to trends that would otherwise be obscured by disparate systems. Dive deep into your KPIs to track historical progress and identify opportunities for improvement.

Plus, you can configure notifications to receive alerts and reminders, promoting smooth operations at every level in your plant. With mobile forms at your employees’ fingertips, data collection becomes an ingrained component of your company culture instead of another time-consuming task.

SafetyChain’s superior software architecture is highly configurable to ensure a flawless fit with your facility’s processes, equipment, and routine. Facility audits, user-friendly supplier portals, scorecarding, and other intuitive features make food safety risk mitigation and enterprise-wide traceability simpler and more effective than ever.

- Personal Care

- Cosmetics

- Household Products

- Neutraceuticals

Read How Death Wish Coffee Mastered SQF & Went Paperless

Perfect Co-man & Co-Pack

Contract manufacturing and packaging (“Co-Manufacturing” and “Co-Packaging”) companies face the same regulatory challenges as traditional food and beverage and CPG companies, with the added challenge of not just meeting their customers’ stringent requirements… but perfecting the recipes.

No matter how you make, pack, and ship your product, you must still comply with strict guidelines while maintaining profitability. Communication with customers is essential, but giving timely updates depends on your ability to see into every activity within your facility in real time.

SafetyChain allows you to accelerate performance, simplify compliance, and drive safety and quality. With a dynamic, paperless approach to recordkeeping, intuitive dashboards to track KPIs, and real-time notifications, you’ll have all the tools you need to increase visibility for enhanced plant management. Plus, cloud-based documentation via configurable mobile forms makes compliance with regulatory and customer requirements thorough and more efficient.

- Manage Operations with OEE/SPC

- Help Suppliers Stay Compliant

- Meet Tight Requirements

- Improve Quality

- Shared Performance Data

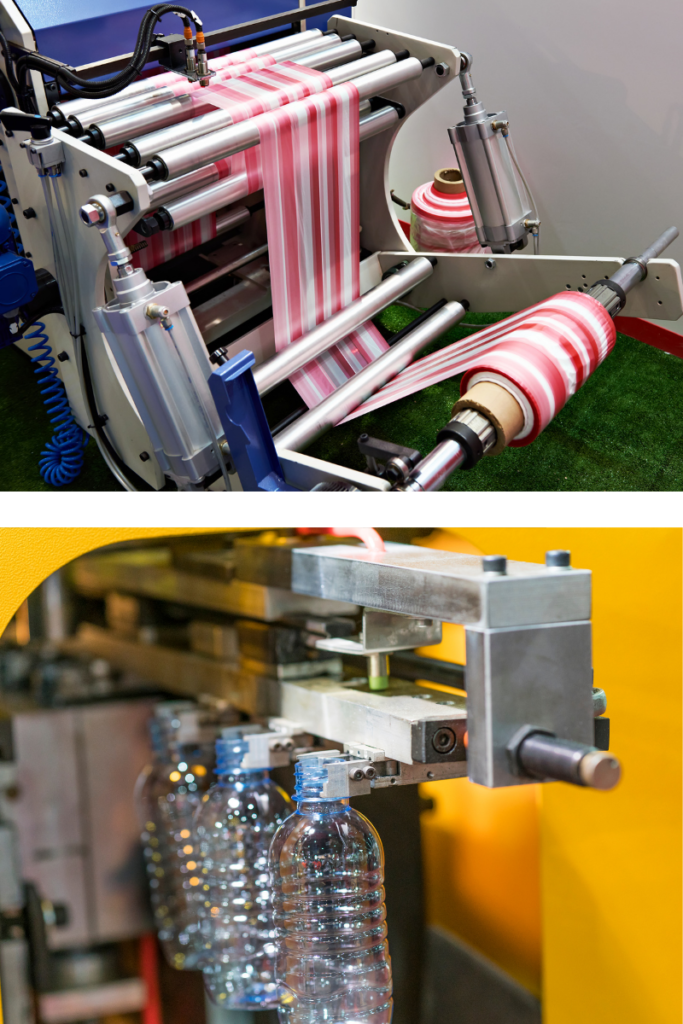

Process Manufacturers

Non-food process manufacturing such as paints, coating, plastics, paper, and packaging faces challenges similar to those seen in Food & Beverage, including the need to keep production lines up while keeping costs down. Similar to Food & Beverage specific manufacturing, process manufacturing relies on ingredients, formulas (known as recipes in F&B), and bulk materials.

Just like the wide variety of products that they produce, process manufacturers have many different focal points and need to solve different problems. Software geared toward discrete or hybrid manufacturing will not work smoothly in a process manufacturing setting. With process manufacturing, the end product is unable to be broken down to its original ingredients, so the software must be able to account for some intricacies. Details such as ingredient inspection, forward and backward lot traceability, the ability to check for inconsistencies in finished goods, and visibility across plants, lines, and batches while recording manufacturing steps and production notes are key in plant management software.

- Paints

- Coating

- Plastics

- Paper Products

- Packaging

“I’m now a step ahead with SafetyChain. No more being reactive, I can spend my time working on things that impact the bottom line, like yield.”

Eric Sorel – Plant Manager